How to deal with pig manure?

With the development of the agricultural economy and technology, the sustainable development ideas and environmental protection technology are gradually becoming a major feature. And the industry of organic fertilizer becomes the main force in the market. According to the feedback of market on organic fertilizer production equipment, we can see that the market is satisfied with the results of organic fertilizer equipment, and it has been developing in the competition.

Pig manure contains 15% of organic matter and low total nutrient content. It has 0.5%~0.6% of nitrogen, 0.45%~0.5% of phosphorus and 0.35%~0.45% of potassium. Pig manure has a finer texture and a more complex composition. It contains protein, fat, organic acids, cellulose, hemicellulose and inorganic salts.

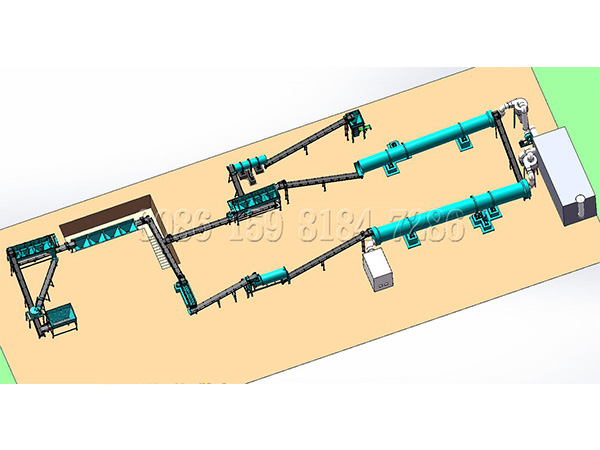

The process of pig manure organic fertilizer production

1.According to the water content of pig manure, you should combine pig manure with appropriate amount of straw powder.Generally, 45% of water content is required for fermentation, that is, when you grasp the materials, the water between fingers does not drip. However, when you loose it, it will disperse immediately. Then add the flour of corn and strains. The corn flour is to increase the sugar content for the fermentation of strains, so that the multidimensional complex enzyme bacteria will quickly take the absolute advantage.

2.You should add the prepared mixture to the mixer for stirring. The stirring must be even and thorough.

3. The mixed ingredients are piled into strips with a width of 1.5 meters to 2 meters and a height of 0.8 meters to 1 meter, which are tossed every 2 days with a compost turner machine.

4. Composting becomes heat in 2 days, odorless in 4th day, loose in 7th day, fragrant in 9th day and fertilizer in 10th day.

(1) On the second day of composting, the temperature can reach 60℃-80℃, which can kill E. coli, eggs and other pests.

(2) The odor of pig manure was eliminated on the 4th day.The compost became loose and dry on the 7th day. And it is covered with white hyphae.

(3) On the 9th day, a scent of distiller’s yeast is emitted.

(4) The fermentation of bacterial fertilizer will be finished on the 10th day.

5. After a little drying, the material can be crushed by a semi-wet material crusher and then granulated by an organic fertilizer granulator, dried and dehydrated by a dryer, and screened by a rotary screening machine. After these processes,the organic fertilizer can be packaged.

The actual quotation of pig manure organic fertilizer line is determined according to the actual needs of customers. Due to the regional climate, source of raw material and different capacity, the choice and price of organic fertilizer equipment are also different. If you want to know more professional and detailed information, please contact Zhengzhou Shunxin Engineering Equipment.